“British custom guitar” gets used loosely. Sometimes it refers to an imported body with cosmetic tweaks; sometimes it means a one-off instrument built start-to-finish in a UK workshop. This guide unpacks what British-built should mean in practice so you can compare options with confidence, and ask the right questions before you put down a deposit.

What “British-built” should mean

At its most honest, British describes where the design and build happen, and who stands behind the instrument afterwards. A British maker should be able to show you the people, the workshop, and how the guitars are made here in the UK. That matters for aftercare (setup tweaks, repairs, upgrades) and for accountability: you can speak to the maker, not a ticketing system. If you’re researching British Custom Guitars, look for pages that describe the team, studio location, and build approach, and check that “made in the UK” or “made in Britain” isn’t just a slogan. Munson’s own overview, for example, clearly states their instruments are “crafted in Britain” and explains the materials and approach. This is backed up by the sought after Made in Britain accreditation.

How British supply chains shape the guitar you get

Local and UK-grown timbers

A uniquely British angle is the availability of home-grown species such as English sycamore (a maple, Acer pseudoplatanus), English walnut, ash, elm and London plane among them. You’ll find respected British luthiers building entire instruments from English timbers, and UK suppliers carrying flamed sycamore/maple body blanks and other tonewoods suitable for electric builds. Beyond tone and aesthetics, the benefit is traceability and fewer carbon miles.

UK electronics partners

Another marker of a British build is the electronics ecosystem: there’s real depth in UK pickup winding. Names you’ll regularly see on British custom jobs include Bare Knuckle Pickups (hand-wound in Cornwall), Old Bones Pickups (Suffolk), Oil City Pickups (London), and Monty’s (Cheltenham). Using local winders makes voicing sessions easier and keeps service within reach.

Sustainability and provenance

Many UK suppliers emphasise sustainably sourced stock and clear provenance, useful if you care where woods come from or prefer avoiding CITES-restricted species. Look for explicit notes on sourcing in a maker’s materials page or supplier listings.

Two routes to a British custom guitar – custom shop vs. bespoke

Most UK makers offer one (or both) of these:

- Custom Shop builds. You start with a refined British model, body outline, ergonomics, and architecture are set. Then you get to configure the important bits: neck profile and depth, fretboard radius, scale, hardware, pickups/switching, and finishes. This route is predictable and typically faster, since the platform is already dialled. A good Custom Shop page will spell out the models and what you can change. For example, Munson’s custom shop page lists Avenger, Tempest, Marauder and Mosquito with configurable options.

- Bespoke / one-off builds. Here you co-design: silhouette, ergonomics, electronics architecture, and finish are open. It’s best when you want something outside existing templates or have specific ergonomic needs. A clear Bespoke page should outline process, scope and decision points.

Neither path is “better”. The right choice depends on whether you value speed and budget predictability (custom shop) or design freedom (bespoke).

Spec choices that matter in a British context

- Neck geometry and scale

Profile (soft-V/C/D), depth at 1st/12th fret, fretboard radius and fret size decide whether the guitar feels “right” in your hands. Scale length changes both feel and how pickups “hear” the string. UK builders may typically publish these measurements (often in millimetres) and are happy to discuss tweaks before anything gets cut. - Electronics voice

Pickups set the broad character; wiring, switching and pot values determine how usable the in-between tones are. Many British builds pair UK-wound pickups with modern switching options so you’re not stuck with a single flavour. Look for model or spec pages that show the exact sets and circuits on offer, or the option to discuss this with the luthier. - Body ergonomics and weight

Many British builders prioritise comfort and balance over chasing the absolute lightest body. Look for thoughtful forearm/rib contours, a tidy neck-heel, and a realistic finished-weight range rather than a single “hero” number, plus photos showing how those carves are executed. Munson goes next level, by being able to accurately calculate the finished weight of the instrument, with its various sculpted elements, based on the weight of the wood blanks. Perfect when you want to dial in the best weight for you. - Hardware & setup practicality

Bridges, trems and nuts affect tuning stability and day-to-day feel. A good spec sheet will state the exact bridge/trem model, string spacing and nut material, and note any maintenance expectations. Being able to source spares and get aftercare in the UK is a practical plus.

Finishes, briefly (and why they matter)

- Nitrocellulose cures thin and hard, ages gracefully and takes time—plan for the curing window in your timeline.

- Oil/wax systems give a fast satin feel and let grain show; great for players who prefer a “dry” neck.

- Poly finishes are durable and consistent for heavy gigging.

Strong model pages show real photos (ideally on UK/European woods) so you can see how stains and clear finished take on different grains rather than relying on swatches alone. A local luthier will use off-cuts of the actual wood used to make the guitar to test colours and finishes to make sure they look good when applied to the instrument.

Timelines (why British builds take the time they take)

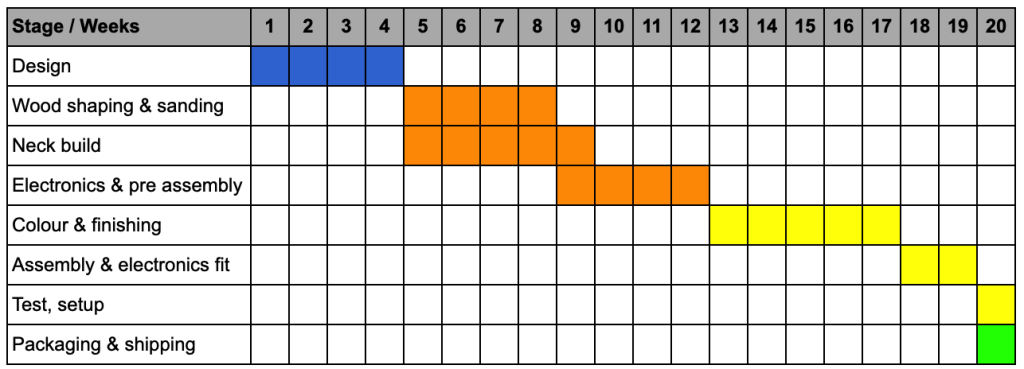

Lead time is the sum of wood prep and stability checks, machining and hand work, finishing and curing, assembly, and setup. Complexity (binding, inlay, bespoke hardware) and mid-build changes add steps, especially with nitro, which simply needs time. Responsible shops publish ranges and outline what’s flexible at each stage; custom shop builds are usually quicker than true one-offs.

Left-handed and accessibility

If you’re a southpaw or need specific ergonomic tweaks, look for explicit left-handed options or a dedicated LH page. That’s a strong sign the workflows and templates already exist for left hand builds. Remember, that for a left handed guitarist, the right guitar means everything.

A quick checklist for spotting genuinely British custom work

- Workshop & story: Can you see who’s building and where? UK address present? Process explained in plain English?

- Models & scope: Are custom shop models listed with configurable options, and is there a separate, detailed explanation for bespoke?

- Materials: Do they discuss UK/European timbers or reclaimed stock, and why they choose them? Any examples of English sycamore/walnut/elm/plane?

- Electronics partners: Do they work with UK pickup makers (BKP/Old Bones/Oil City/Monty’s etc.) or offer UK-sourced winds?

- Aftercare: Is there an easy way to contact the builder?

If you want to see how one British workshop approaches it

These Munson pages are a practical starting point. Browse them like a buyer’s checklist, not a brochure:

- Bespoke guitars: process, scope, and what’s possible.

- Custom Shop guitars: model overviews, configurable options, and an online builder.

- Model pages to compare ergonomics/specs:

- Custom Guitar Experience: Where you are part of the British custom guitar and bass build experance.

- Our Guitars (materials & philosophy)

- Left-Handed options

- A bit about us

- Contact (for a quick chat)

Why it’s worth it – the British bit

Choosing a British custom guitar isn’t about flag-waving; it’s about knowing who built your instrument, where the wood came from, and who’ll look after it when real life happens. It’s the difference between a spec sheet and a handshake: traceable materials, plain English communication, and workmanship you can stand in front of. The result is a guitar made to measure for your playing, balanced on the strap, honest at the amp, and up for work night after night.

Commissioning here at home also keeps the circle small: local tonewoods where possible, UK pickup winders you can talk to, and aftercare that doesn’t involve shipping a guitar halfway round the world. It’s craft you can visit, timelines you can understand, and a maker who will tell you what’s sensible, and what isn’t, before anything is cut.

In short: British-built means accountable, serviceable, and built properly. If that’s what you’re after, the next step is simple Pick your route (Custom Shop or Bespoke), ask the right questions, and speak to the maker. The rest follows.